Floor Paint Anti Slip - 5L - White & Black

SKU: FS-5FLOORPAINTAS9001

Product Features:

- Exceptional slip resistance

- Great for warehouses, factories, workshops and heavy foot traffic

- Use it on most surfaces - concrete, wood, stone and cement

- Stands up to oil and grease

FREE Standard Delivery*

Order from floorsaver and get free standard delivery on your order when you spend over £100. (For smaller orders, a carriage charge does apply.)

Choose standard delivery and we'll get your order to you within 2-3 working days*. Our warehouse is closed at the weekend, so orders placed on a Saturday or Sunday will be processed on the following Monday.

*Delivery exclusions

We only deliver to the UK mainland, excluding the Scottish Highlands. That means we're unable to deliver to Northern Ireland, Ireland, Isles of Scilly, Isle of Wight or the Channel Islands. We are also unable to provide next day delivery to Scotland.

Collapsible content

-

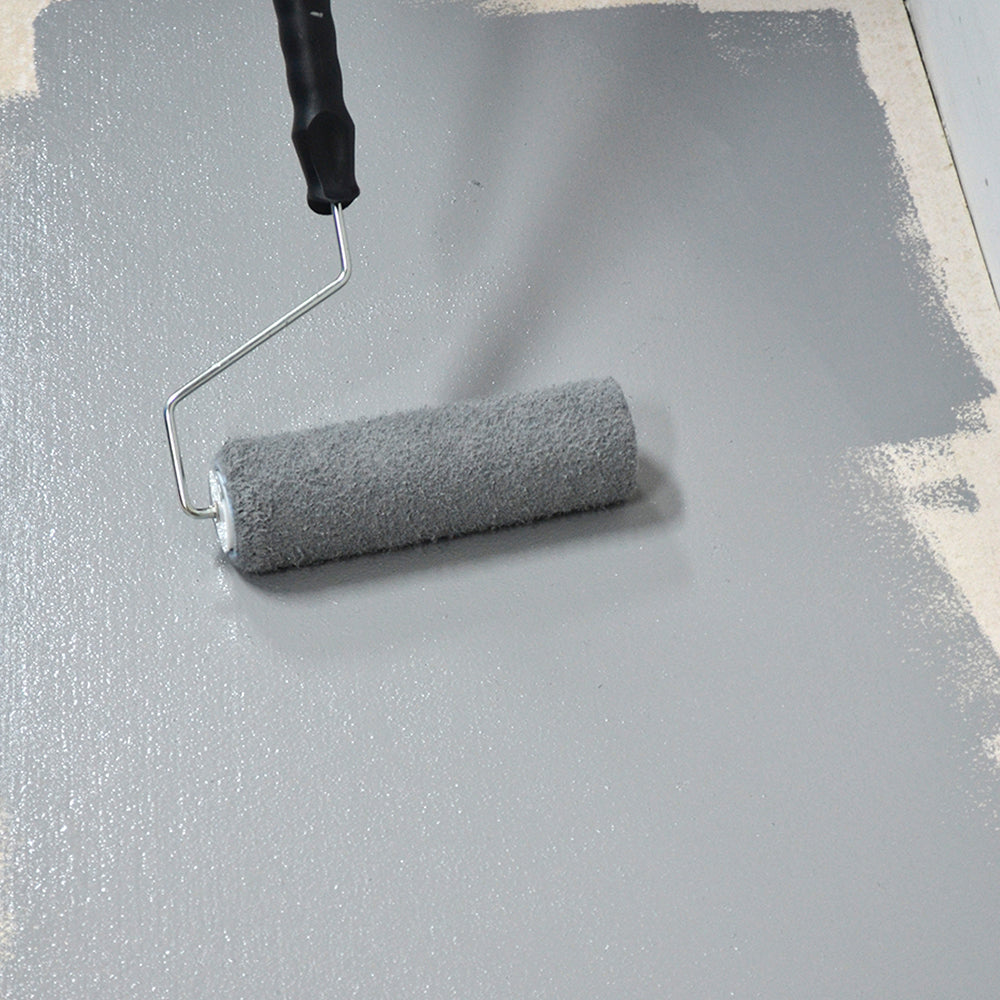

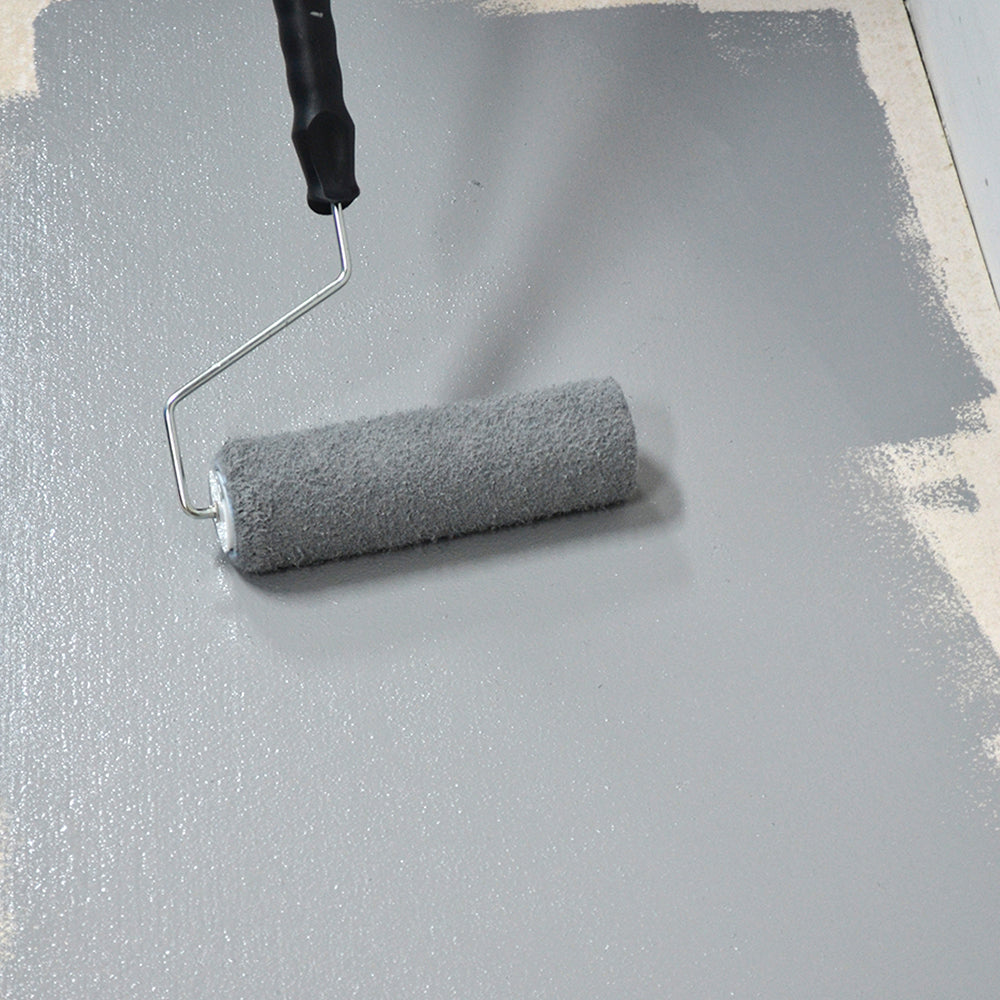

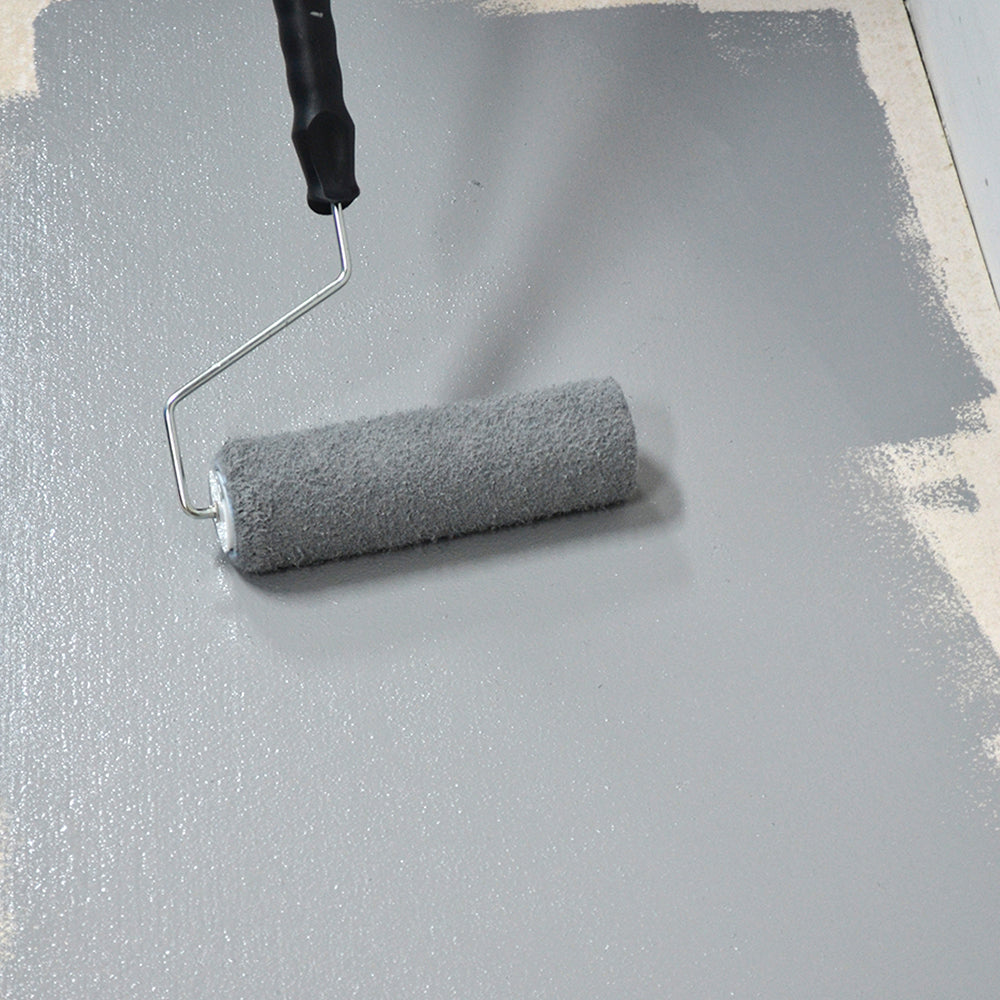

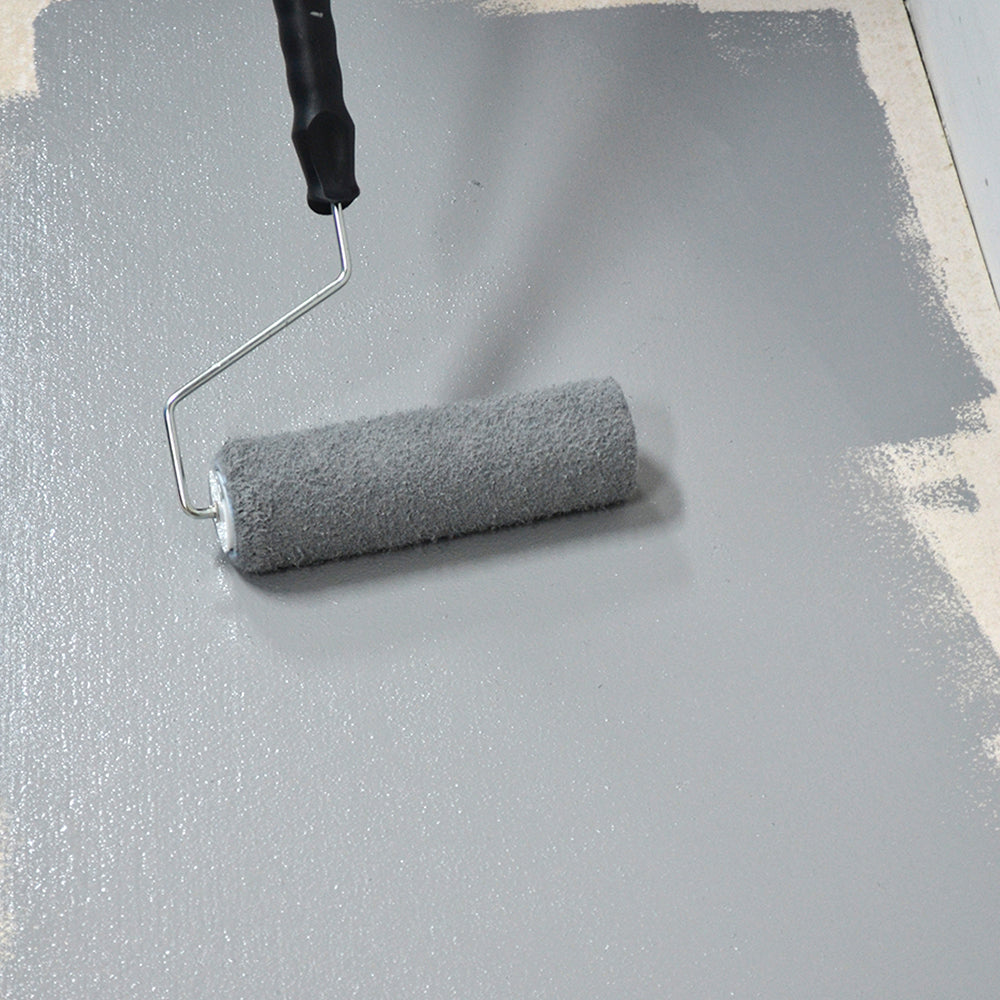

floorsaver Floor Paint dust proofs, seals and protects internal concrete floors. Two coats provide a glossy, easily cleaned finish. It can be applied to bare concrete or existing well bonded paint. When recoating existing floor paint of a similar colour, one coat is generally all that is needed.

You might also like:

-

Cleaner Degreaser for oily and dusty floors

-

Floor Etcher for new concrete

- A Floor Roller for the best results

-

Concrete Floor Paint Anti Slip for a slip resistant finish

- Universal Concrete Primer for better adhesion

Please note - orders for the Yellow colour of our Floor Paint will be labelled as Hazard Paint.

-

Cleaner Degreaser for oily and dusty floors

-

Specification Value Product usage - Interior

Product uses - Bare Concrete

- Wood

- Metal

- Existing Well Bonded Paint

Product shelf life 3 years, if unopened and should not be allowed to freeze. Minimum application temperature 15°C Product drying time At 15-20°C: Recoat - 16 hours (if there is a time lapse between coats, the second coast must be applied within 5 days of the first coat). Touch Dry - 10 hours. Light Foot Traffic - 24 hours. Full Use - 36 hours. Please check that the paint has fully cured before putting into full use. Product coats 2 coats usually required, although 1 coat may be enough if painting over an existing floor paint of a similar colour. Product coverage 5L covers up to 40m² per coat. 2.5L covers up to 20m² per coat Product properties Resists spills of oils and grease Product applications Use the whole tin of Anti Slip Aggregate for the 5L pack size and half for the 2.5L. Usable working time (at 15°C) 2 hours. Epoxy Floor Paint is a two part epoxy resin supplied as a tin of resin and a tin of curing agent. Once the contents of the two tins have been mixed together, a reaction takes place which causes the product to cure. This means that one 5L tin can be used for 2 coats. It will cover 30m² with one coat, but if you have for example, 15m², you can use half the 5L tin for the first coat, then wait for the first coat to dry before using the other half for the second coat - it will have gone off in the tin. This is why we also make a 2.5L size. This covers 15m² with one coat, so select two of these if you want to apply 2 coats to an area of up to 15m². You can combine 5L (30m²) and 2.5L (15m²) for areas which are not multiples of 30m² in size and more than one coat is required. For example, to cover 45m² with 2 coats use 1 x 5L and 1 x 2.5L for the first coat and same again for the second. If you have any questions please let us know. -

Product Information Sheet

DownloadSafety Data Sheet

DownloadSafety Data Sheet - Non Slip Additive

DownloadFloorsaver RAL Colour Chart

Download

Collapsible content

Description

floorsaver Floor Paint dust proofs, seals and protects internal concrete floors. Two coats provide a glossy, easily cleaned finish. It can be applied to bare concrete or existing well bonded paint. When recoating existing floor paint of a similar colour, one coat is generally all that is needed.

You might also like:

-

Cleaner Degreaser for oily and dusty floors

-

Floor Etcher for new concrete

- A Floor Roller for the best results

-

Concrete Floor Paint Anti Slip for a slip resistant finish

- Universal Concrete Primer for better adhesion

Please note - orders for the Yellow colour of our Floor Paint will be labelled as Hazard Paint.

How to Use

Technical Spec

| Specification | Value |

|---|---|

| Product usage |

|

| Product uses |

|

| Product shelf life | 3 years, if unopened and should not be allowed to freeze. |

| Minimum application temperature | 15°C |

| Product drying time | At 15-20°C: Recoat - 16 hours (if there is a time lapse between coats, the second coast must be applied within 5 days of the first coat). Touch Dry - 10 hours. Light Foot Traffic - 24 hours. Full Use - 36 hours. Please check that the paint has fully cured before putting into full use. |

| Product coats | 2 coats usually required, although 1 coat may be enough if painting over an existing floor paint of a similar colour. |

| Product coverage | 5L covers up to 40m² per coat. 2.5L covers up to 20m² per coat |

| Product properties | Resists spills of oils and grease |

| Product applications | Use the whole tin of Anti Slip Aggregate for the 5L pack size and half for the 2.5L. Usable working time (at 15°C) 2 hours. Epoxy Floor Paint is a two part epoxy resin supplied as a tin of resin and a tin of curing agent. Once the contents of the two tins have been mixed together, a reaction takes place which causes the product to cure. This means that one 5L tin can be used for 2 coats. It will cover 30m² with one coat, but if you have for example, 15m², you can use half the 5L tin for the first coat, then wait for the first coat to dry before using the other half for the second coat - it will have gone off in the tin. This is why we also make a 2.5L size. This covers 15m² with one coat, so select two of these if you want to apply 2 coats to an area of up to 15m². You can combine 5L (30m²) and 2.5L (15m²) for areas which are not multiples of 30m² in size and more than one coat is required. For example, to cover 45m² with 2 coats use 1 x 5L and 1 x 2.5L for the first coat and same again for the second. If you have any questions please let us know. |