lsocrete 1500P - 25kg

SKU: FS-XIS25TR

In stock

Product Features:

- Fast curing - Can be coated in 24 hours cure time, can be dry polished in 24 hours.

- Self-levelling - for an even finish

- Strong - Durable surface achieving a compressive strength of 7,000 psi.

- Micro-Fibre Enhanced - Improves various physical properties and reduces shrinkage.

FREE Standard Delivery*

Order from floorsaver and get free standard delivery on your order when you spend over £100. (For smaller orders, a carriage charge does apply.)

Choose standard delivery and we'll get your order to you within 2-3 working days*. Our warehouse is closed at the weekend, so orders placed on a Saturday or Sunday will be processed on the following Monday.

*Delivery exclusions

We only deliver to the UK mainland, excluding the Scottish Highlands. That means we're unable to deliver to Northern Ireland, Ireland, Isles of Scilly, Isle of Wight or the Channel Islands. We are also unable to provide next day delivery to Scotland.

Collapsible content

-

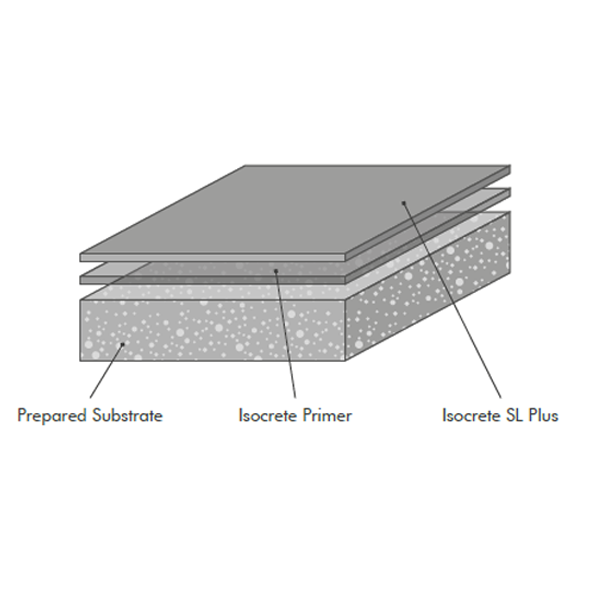

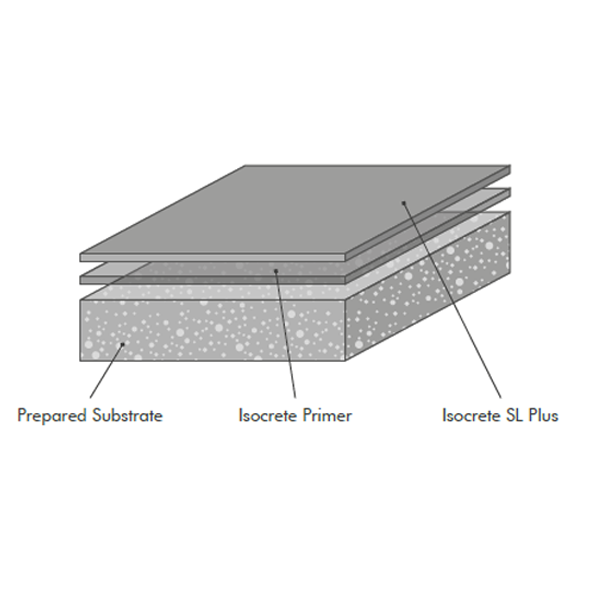

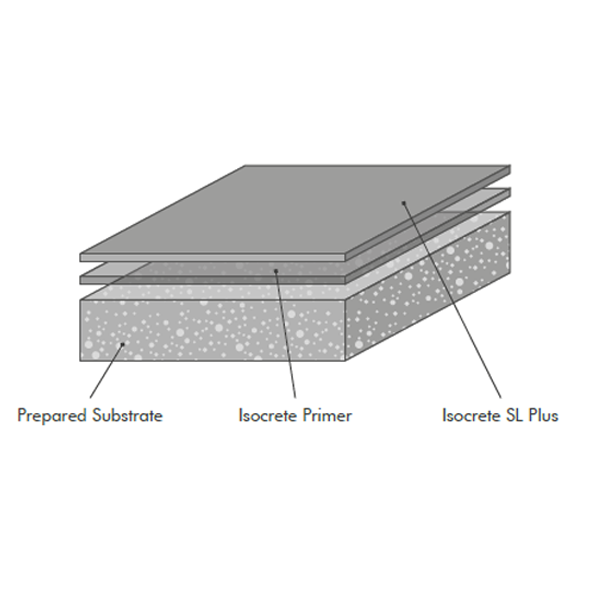

A micro-fibre reinforced, cementitious, single component self-levelling surfacing compound. Designed for use on new or worn concrete substrates as an underlayment or finished wear surface that can be polished to achieve a high gloss finish.

Uses

Suitable for floors in office buildings, shops, public buildings, schools, hospitals, airports and prisons. lsocrete 1500P is easy-to-use, provides excellent adhesion and long-term

durability.

Can be covered with a variety of floor finishes including epoxy terrazzo, resinous flooring, tile, vinyl and carpet. -

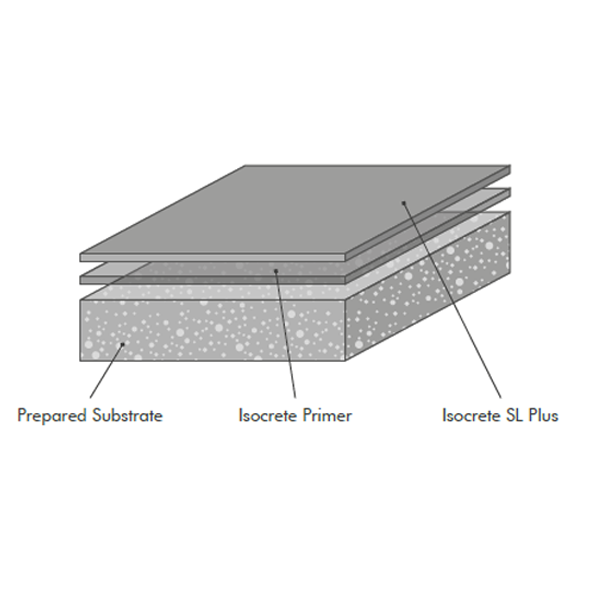

Preparation

- Prepare the surface by enclosed shot-blasting or scarification. Finish edges with a Steel Float. Remove all residues to leave a dry and dust free open textured surface. Seal all openings and holes to prevent leaks.

Mixing

- Pour the powder into a mixing container adding 4.5 - 4.8 litres of water (per 25kg). Stir with our Mixing Blade until a smooth consistency is achieved. Mix with our Mixing Blade until a smooth consistency is achieved.

Application

- Lay the mixed "Screed" in a continuous operation on the primed surface.

- Release small air bubbles with a spiked roller or tee-bar within 5 minutes of placing.

-

Specification Value Product usage - Interior

Product shelf life 6 months, if unopened. Store in temperature between 6°C and 25°C. Product drying time Protect from strong draughts and sunlight for 6 hours. Light foot traffic after 2-4 hours. Protect from other trades and traffic after installation. Product coverage Primers: lsocrete Primer Plus at 150-250 sq ft/ gal

OR: Key 502/Flowprime Epoxy Primer at 80 sq

ft/gal plus 30 mesh sand broadcast to excess

Mortar:* lsocrete 1500P at 20 sq ft/ bag yields 1 / 4"

Mortar consists of 50 lb bag lsocrete 1500P and 4 .5 to 5

quarts of cool potable water, yielding 0.5 cubic feet. An

additional pint of water may be added if required.

*Yield with 50% extension by weight with 3/8" clean pea

gravel : 0.6 cubic foot (for applications from > 2" up to

3" depth). 1 / 4" is minimum placement thickness for non-polished topping applications. 3/ 8" is minimum

placement thickness for polishing applications and

requires epoxy primer plus sand broadcast.

Coverages listed are theoretical, actual coverages may

vary based on substrate and site variations. Detailed

application instructions are available upon request.Product properties Flow rate 220 - 240mm.

Water Addition 4.5 - 4.8 litres water (per 25kg bag).

The recommended substrate temperature is 15 - 25°C. -

Product Information Sheet

DownloadSafety Data Sheet

Download

Collapsible content

Description

A micro-fibre reinforced, cementitious, single component self-levelling surfacing compound. Designed for use on new or worn concrete substrates as an underlayment or finished wear surface that can be polished to achieve a high gloss finish.

Uses

Suitable for floors in office buildings, shops, public buildings, schools, hospitals, airports and prisons. lsocrete 1500P is easy-to-use, provides excellent adhesion and long-term

durability.

Can be covered with a variety of floor finishes including epoxy terrazzo, resinous flooring, tile, vinyl and carpet.

How to Use

Preparation

- Prepare the surface by enclosed shot-blasting or scarification. Finish edges with a Steel Float. Remove all residues to leave a dry and dust free open textured surface. Seal all openings and holes to prevent leaks.

Mixing

- Pour the powder into a mixing container adding 4.5 - 4.8 litres of water (per 25kg). Stir with our Mixing Blade until a smooth consistency is achieved. Mix with our Mixing Blade until a smooth consistency is achieved.

Application

- Lay the mixed "Screed" in a continuous operation on the primed surface.

- Release small air bubbles with a spiked roller or tee-bar within 5 minutes of placing.

Technical Spec

| Specification | Value |

|---|---|

| Product usage |

|

| Product shelf life | 6 months, if unopened. Store in temperature between 6°C and 25°C. |

| Product drying time | Protect from strong draughts and sunlight for 6 hours. Light foot traffic after 2-4 hours. Protect from other trades and traffic after installation. |

| Product coverage |

Primers: lsocrete Primer Plus at 150-250 sq ft/ gal OR: Key 502/Flowprime Epoxy Primer at 80 sq ft/gal plus 30 mesh sand broadcast to excess Mortar:* lsocrete 1500P at 20 sq ft/ bag yields 1 / 4" Mortar consists of 50 lb bag lsocrete 1500P and 4 .5 to 5 quarts of cool potable water, yielding 0.5 cubic feet. An additional pint of water may be added if required. *Yield with 50% extension by weight with 3/8" clean pea gravel : 0.6 cubic foot (for applications from > 2" up to 3" depth). 1 / 4" is minimum placement thickness for non-polished topping applications. 3/ 8" is minimum placement thickness for polishing applications and requires epoxy primer plus sand broadcast. Coverages listed are theoretical, actual coverages may vary based on substrate and site variations. Detailed application instructions are available upon request. |

| Product properties |

Flow rate 220 - 240mm. Water Addition 4.5 - 4.8 litres water (per 25kg bag). The recommended substrate temperature is 15 - 25°C. |